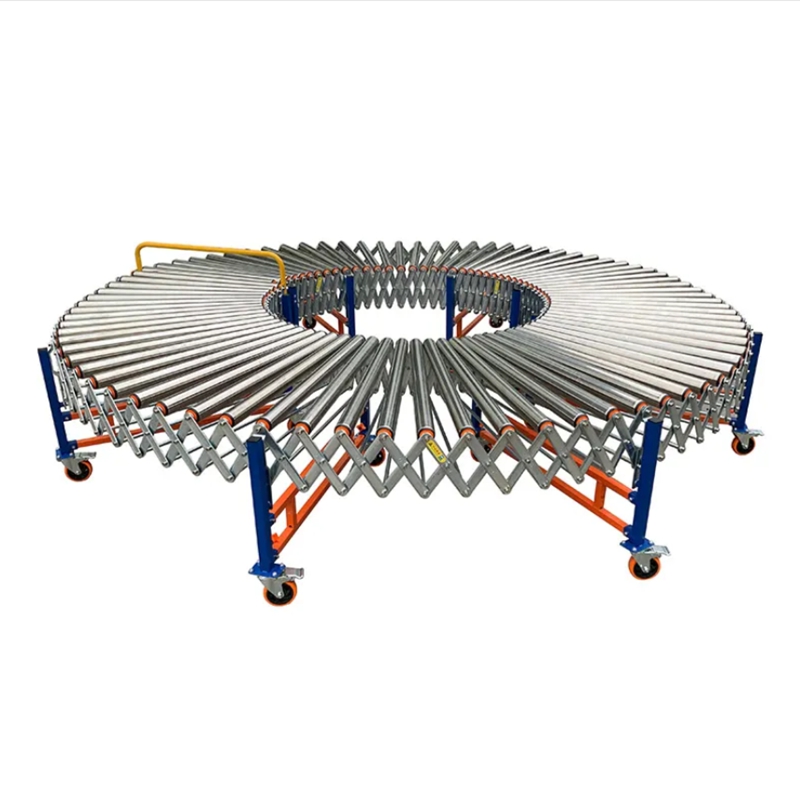

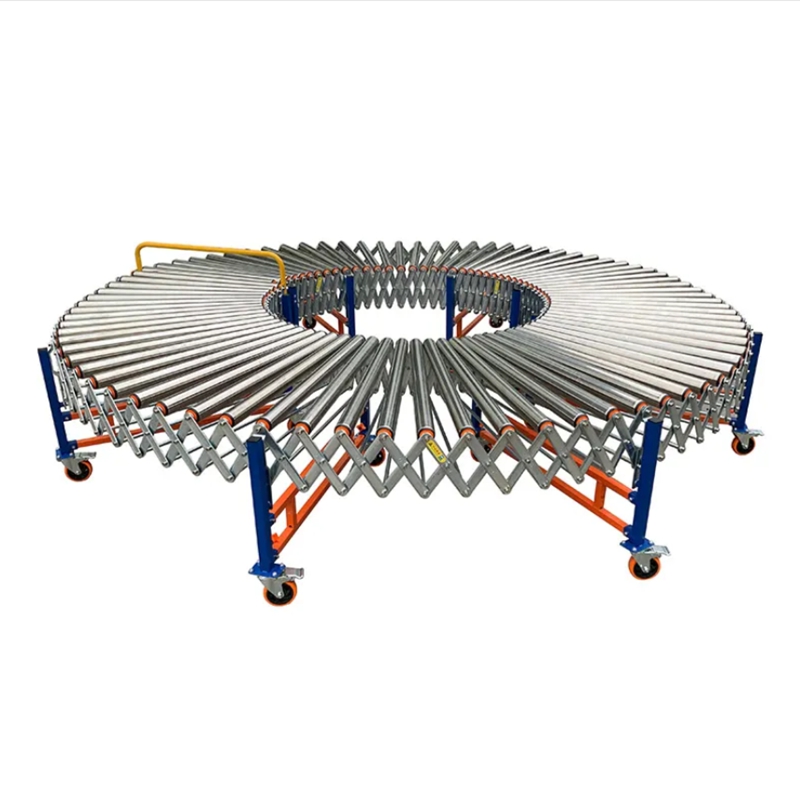

Motorized flexible conveyor

Motorized flexible conveyor is a power conveyor that can freely extend and contract within its length range. Its height is adjustable, and conveying surface can be entended, tilted or bended to a curve (or a circular arc) by requirements. It is mainly used for loading and unloading in workshop, warehouse and goods yard etc as well as for goods receiving and delivery in production packing line, temporary conveyor line, logistics distribution etc, especially suitable for conveying carton goods with flat bottom. During conveying process, goods are conveyed quickly and safely between two connections, improving work efficiency and recuding labor intensity.

Motorized flexible conveyor is a power conveyor that can freely extend and contract within its length range. Its height is adjustable, and conveying surface can be entended, tilted or bended to a curve (or a circular arc) by requirements. It is mainly used for loading and unloading in workshop, warehouse and goods yard etc as well as for goods receiving and delivery in production packing line, temporary conveyor line, logistics distribution etc, especially suitable for conveying carton goods with flat bottom. During conveying process, goods are conveyed quickly and safely between two connections, improving work efficiency and recuding labor intensity.

Using ¢50 single row of “O” belt driven roller for conveying surface

Width of conveying surface: 450、500、600

Width of conveying surface: 450、500、600

When conveyor is fully extended, carrying capacity per unit between every two adjacent support should be less than 30Kg (no impact load state)

Electric motor is driven by “O” belt, line speed of roller surface is 25m/min, with electric cabinet (flexible conveyor with speed adjustable for selection, speed adjustable range: 10-35m/min, with electric cabinet). Starting switch and emergency stop switch are positioned at the end of flexible conveyor for convenience.

HUZHOU DP TECHNOLOGY CO.,LTD

HUZHOU DP TECHNOLOGY CO.,LTD